Raw Materials for Cement Manufacture

Raw materials for cement manufacture. The first step in the manufacture of portland cement is to combine a variety of raw ingredients so that the resulting ...

WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Raw materials for cement manufacture. The first step in the manufacture of portland cement is to combine a variety of raw ingredients so that the resulting ...

Ball Mill In A Cement Plant : The general mining methods are surface mining, while some silicates, such as sand, are commonly mined using dredges, from lakes ...

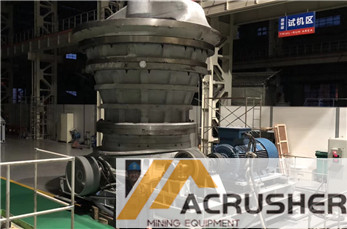

A mediumsized dry process roller mill. ... In general, cement raw materials are mainly quarried, and so contain a certain amount of natural moisture.

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

Cement grinding Vertical roller mills versus ball ... finer than raw meal • the feed to a cement mill is often ... of the mill and the grinding process.

• What is Cement? • History • Overview of the Cement ... for moist raw materials • Wet process high fuel requirements ... cement mill clinker gypsum 95% 5% ...

Portland Cement Manufacturing Process Description17 ... In the wet process, water is added to the raw mill during the grinding of the raw materials in

industrial case study: the cement industry calmac study id: final report prepared for pacific gas and electric company san francisco, california

Cement Manufacturing Process Phases. Production of cement completes after passing of raw materials from the following six phases. These are; Raw material .

OPERATIONAL EXPERIENCE FROM THE UNITED STATES'' ... CEMENT GRINDING IN A VERTICAL ROLLER MILL The differences between raw and cement grinding ... VRM for Cement PROCESS

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology

Slag is the glasslike byproduct left over after a desired metal has been separated (, smelted) from its raw ore. Slag is usually a mixture of metal oxides and ...

Product d ata Sheet ceMeNt Lafarge PortLaNd ceMeNt Lafarge Portland Cement is a high quality, costeffective basic building material used in virtually all forms of ...

Grinding occurs at the beginning and the end of the cement making process. Approximately tonnes of raw materials are required to produce 1 tonne of finished

Cement manufacturing process | CEMBUREAU. Cement manufacturing process. . clinker is produced from raw materials. In the second step cement is . The second .

Heavyduty performance 2 Ideal for both prehomogenisation and buffer storage of raw materials, FL stacker and reclaimer systems have an impressive track record ...

raw mill process in cement industry ppt pdf report India ... cement mill process pdf in tamil language. cement plant operations handbook for dry process plants pdf ...

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing ...

Full Vent System Clinker Collector Gypsum Separator Collector To Product Storage Mill Collector OSepa Separator Primar Air Secondary Air Finish Mill Mill

The initial step in ceramic tile manufacture involves mixing the ingredients. Sometimes, water is then added and the ingredients are wet ...

Environmental, Health, and Safety Guidelines CEMENT AND LIME MANUFACTURING APRIL 30, 2007 4 WORLD BANK GROUP • Developing a staged combustion process .

An Energy Environment Conscious, Sustainable Prosperous Organization * * * * * * * * * * * * * INITIATIVES RESULTS Running two cement mills with one roller press ...

Images forraw mill in cement industry pdf Cement raw material has been almost ... In the dry process, crushed raw materials are dried in a cylindrical rotary drier ...

Application of SuperfineTM Iron Oxide in Concrete PRECAST PRODUCTION Colour is increasingl y contributing to the profit and success of most concrete masonry and paver

WhatsApp)

WhatsApp)